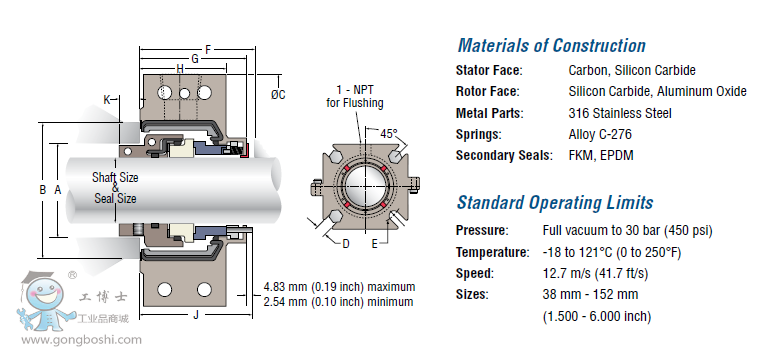

With only two major components, the PSS III split seal simplifies installation without requiring equipment tear down. Semi-cartridge rotating and stationary assemblies eliminate equipment measurements and handling of small intricate components, including seal faces and gaskets.Innovative design with enhanced pressure capability makes the PSS III ideal for paper mills, waste water treatment facilities, soda ash processing and light chemical plants.

Features and Benefits

• No need to completely dismantle the pump and primary driver for seal installation. The PSS III installs around the shaft, outside the seal chamber.

• Easy installation with minimal effort due to the unitized component, semi-cartridge design.

• Product leakage across the faces is minimized by maintaining rotor and stator face squareness with a robust, extended rotor assembly.

• Installation tools are included with the seal. Only one wrench for the gland bolts is required for installation.

• Installation errors are reduced through the use of integral setting tabs on the seal components. No need to measure and mark at the point of installation.

• The PSS III can handle mixer equipment runout up to 1.5 mm (0.060 inch) TIR radial shaft movement,accommodating demanding mixer characteristics.

• Higher pressures or lubricating medium is no problem.The positive drive rotor is held firmly in place by more set screws.

OPERATING PARAMETERS

更多美國福斯Flowserve產(chǎn)品及應(yīng)用��,歡迎登陸:www.flowserve.gongboshi.com其他工業(yè)類產(chǎn)品����,歡迎登陸工博士工業(yè)品商城:podvhdv.cn